PA’s Abrasive Blast Cleaning Specialists

Surtech Industries offers a full suite of blast cleaning services for PA businesses. With over 30 years of serving the York and surrounding Lancaster area, we are able to offer an outstanding commitment to quality and consistency, fast turnaround times and excellent customer service. From our 66,000 square foot facility, we are able to accommodate large volume orders and tier 1 sourcing for the automotive and manufacturing industries.

Businesses throughout PA use our abrasive blast cleaning services for a number of specific applications, including surface prep and cleaning, corrosion and oxidation removal, small parts prep and pipe interior cleaning. Contact our team today for more information about blast cleaning for metal prep or other metal finishing services we offer.

Manual Pressure Blasting (up to 120psi)

- Material is reclaimed and classified to ensure consistent blast profiles and surfaces conditioning.

- Manual abrasive blasting size constraints are 96 inches wide by 144 inches high by 288 inches long.

- Maximum weight is 5000 pounds.

Automated Blast Cleaning and Prep

Wheelabrator style blast equipment is utilized with steel shot media.

- Primarily used for sand and die casting preparation.

- Parts size envelope 12 inches wide by 24 inches long by 12 inches deep.

- Weight maximum is 25 pounds.

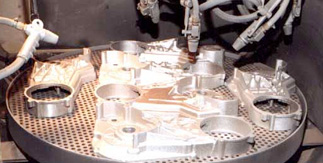

Roto Blast Multi-gun Siphon Abrasive Blast Cleaning

- Aluminum oxide media primarily used for steel/aluminum prep.

- Table size 48 inch diameter.

- Weight maximum is 250 pounds.

Contact Us For Help With Your Project

Quality Assurance

The ongoing success of Surtech Industries is supported by our strong commitment to providing high quality blast cleaning services for businesses in PA and beyond. We consistently deliver a reliable standard of quality on everything we do. Our customers rely on us for abrasive blast cleaning and metal prep that meets the demanding tolerances of today’s industries, and we’ve implemented processes to ensure that. Performance testing can be provided to meet SSPC specifications. Surtech Industries follows an ISO 9000:2008 compliant quality system.

Whether you need manual pressure blasting, Wheelabrator-style automated blast cleaning for sand and die-cast preparation or Roto-Blast multi-gun steel/aluminum metal blast prep, York, PA’s automated blast cleaning experts can help.

Contact Us!

- Address:

- 915 Borom Rd.

York, PA17404 - Phone:

- 717-767-6808

1-800-745-8176 - Online:

- Contact Us to request a free quote!

- Employee Directory:

- View our Employee Directory.

Definition:

Abrasive blast cleaning entails the forceful direction of abrasive particles against the surface of a product, to remove contaminants or to condition the surface for subsequent finishing. Present capabilities offer a wide range of manual and automated blasting processes to provide surface Ra finishes and cosmetic appearances up to a white metal designation (SSPC-SP10). Blast media include aluminum oxides, steel shot and grits, glass bead, and plastic media.